Right now i am trying to locate a factory rod (from another application) to allow the use of SII short compression height pistons with a rod longer than the factory SI/EV6 i havent gotten an exact measurement but the SI rod is dam near 5.9 inches c to c and using the SI piston means i need to find a factory rod ~ 6.1-6.15 in length

SII guys only wish they could fit a rod that long in a short deck...

on this same note a SI guy could get a crank with a larger stroke while using the factory SI rod with a factory or forged aftermarket SII piston, cheap stroker...

well onto the pics...

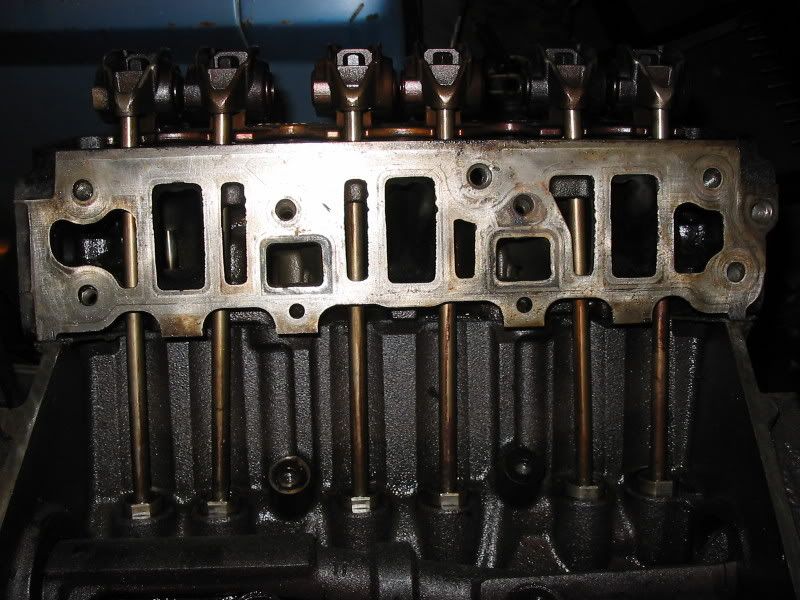

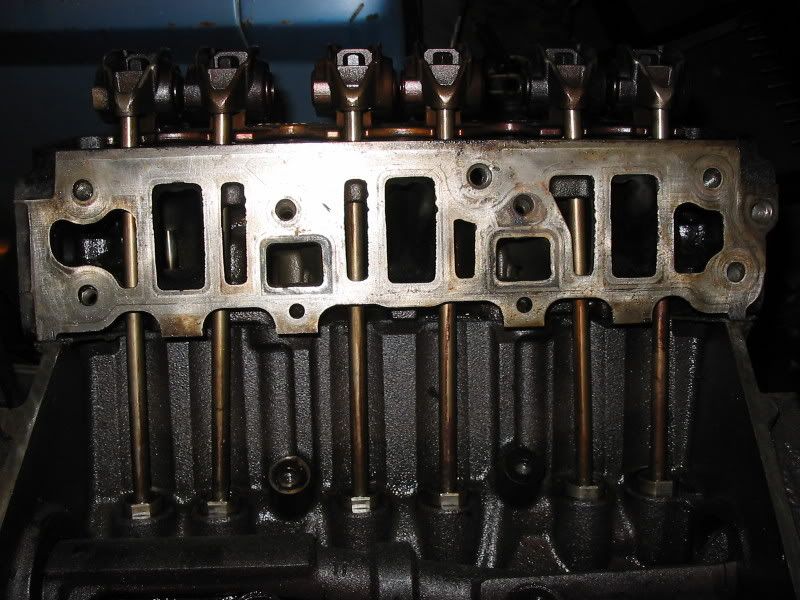

this is the SI/SII Hybrid (by now ya'll know i'm talking about the EV6/Ecotec) the end gaps under the intake is 1 inch, the sides are approx 1 5/32 inches

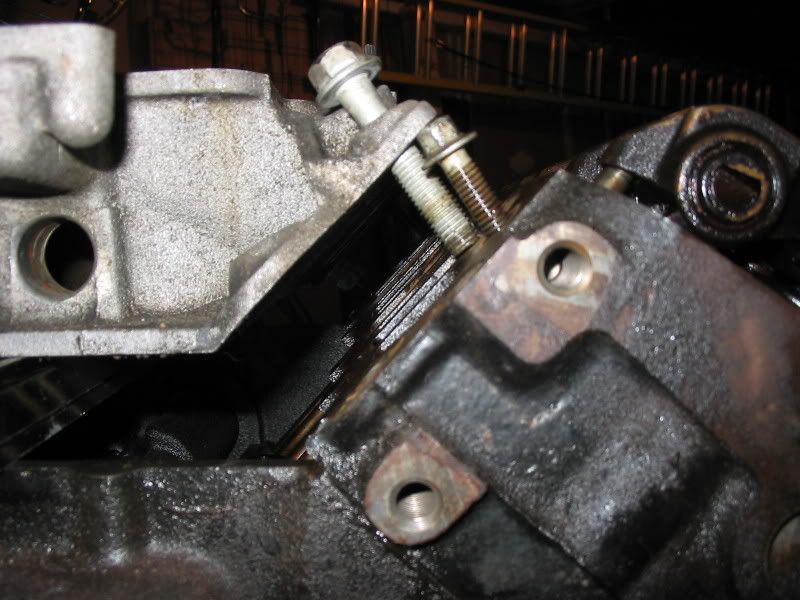

awww yeah SII alternator bracket, SI front lower mount, with SI cover and pump, pulley's all line up all good there.

a high res view of the cylinder bore/head alignment, anyone ever scribe the heads with the bore, my one head needs a .010 ofset pin to move it up, but i want to check more.

nice view of the pushrods...

here's the two coolant ports...these will play into my work on a custom fabb'd intake manifold, i will section out the middle and weld in aluminum to widen it as well as i am looking into external plumbing for the cooling system...i am wanting to see how dificult it would be to make it a reverse flow system, sending the cool coolant straight to the heads and then into the block to prevent hot spots.

Yup it's def an EV6 with symetrical port heads...

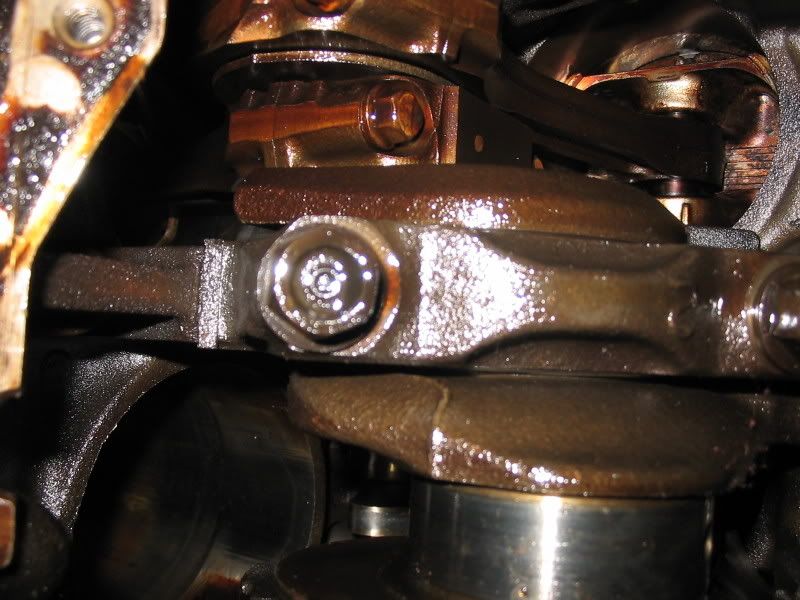

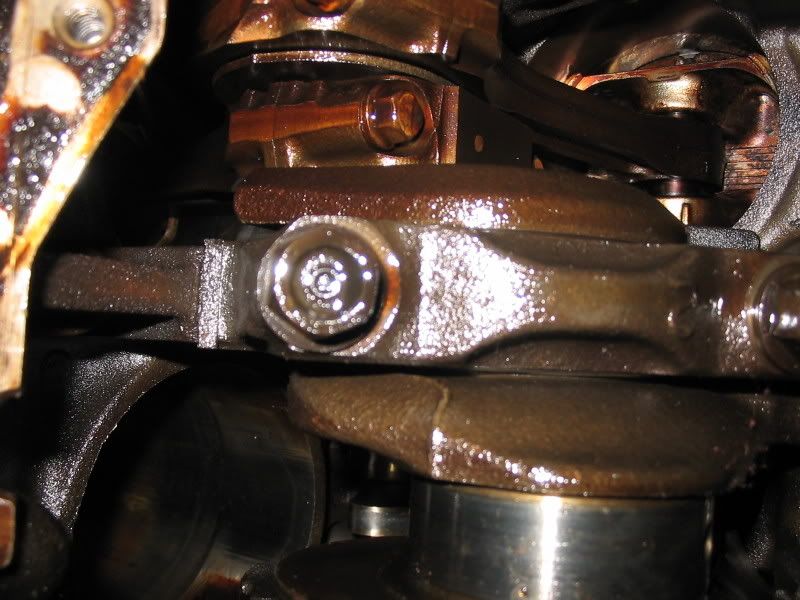

crankcase pics:

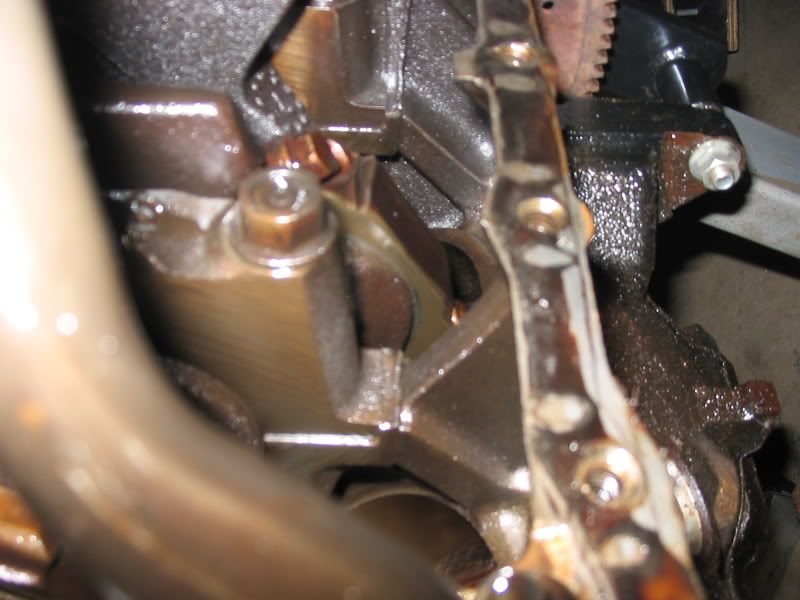

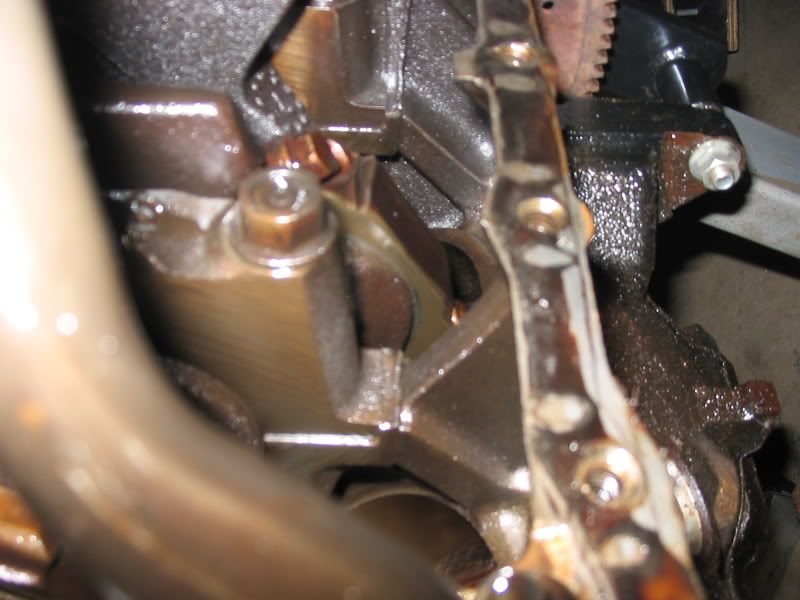

and this is the main reason i have figured it easier and better to widen the LIM than spacers and the problem shown in these pics, bolt angles, you could slot the LIM but that thick of spacers is pretty excessive as are the other problems, this is why i have settled on widening the manifold.

Here i played with flipping the manifold backwards to see if it would be better for external plumbing access to the needed coolant ports in the heads with some work to the T chain cover i could make a bypass for coolant leaving the water pump to the head passages and from there into the block and exiting the front to a remote thermostat/restricter plate.

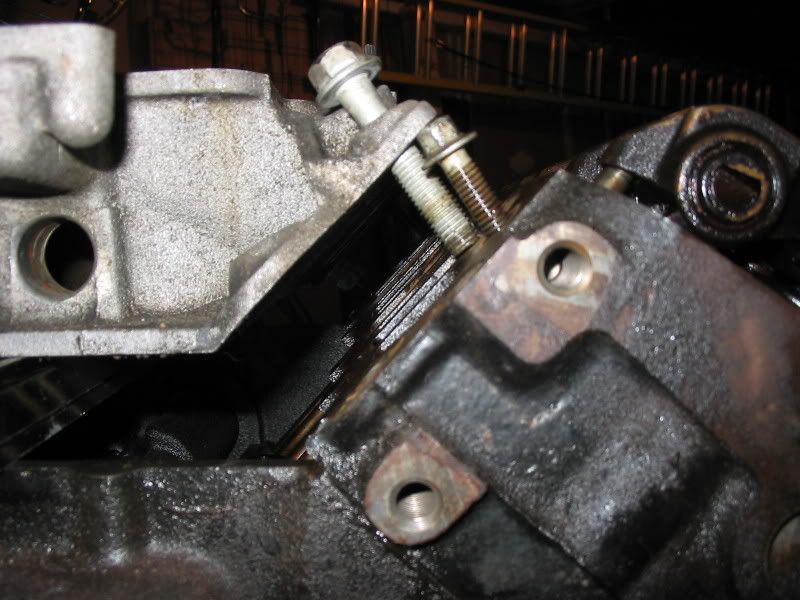

SII FWD front engine mount adaptor bolted on

SI FWD front engine mount bracket and AC comp bracket. either could be used in the final engine, the questions arise for RWD differences, but i'll leave that to ya'll.

I have yet to finish sorting this all out but it looks like the SII alternator bracket can be used with some work or the SI stuff can be retained, i do not have a clue (yet!) what this means as for using the dual belt drive setup on a SII L67 on the SI/SII Hybrid.

a few more pics:

The SII EGR could be used in this setup, but i don’t have smog test's... what? like the guy will ever even think to check for a rear engine...:dancingna

one of the issues of a spacer for the intake...alternator bracket clearance...

the SII tensioner lines up perfectly with the SI pump with SI pulley

for the FWD crowd...now that the SII heads are 1 inch higher there is now an issue with the rear manifold, for turbo vehicles with headers...i dont see an issue but with the firewall on a W body this would probably require rewelding of the rear manifold to lower the angle.

and now to the rods and pistons, i have finally pressed the SI apart and hope to have pics here in the near future (uh yeah the SI rod is a good bit meatier in many ways..but as i said i am looking for longer rods from a different engine/application so that the aftermarket forged SII pistons can be used with an even longer rod at stock stroke is 1.80 rod/stroke angle vs 1.73 for a stock rod SI, which is still way better than a factory SII

but before i go nuts with numbers i have been checking an it would seem that there are different compression height SI pistons...which means several different incarnations of SI (EV6/L27/LN3/LG3) connecting rod length

I'll let your imagination wander...i bet ya can figure which is which..

and the turbo's i'd love to have on the 442...now if i can only steal them off my pop's 07 Peterbilt 13.5L Cat compound turbocharged diesel

_________________

Psychotic Gearhead/Redneck/Mekanik

94 Olds 442 Twin engine's! 6.9L/425 cu inches and 12 cylinders!

13.81 @ over 98 MPH! consistent 1.9s 60'!